Custom Comanche Build 318

#1

Custom Comanche Build 318

Hey guys new to the forum but due to not getting enough info. From just looking it up myself I've turned to the next best thing which would be asking all my fellow mopar guys/gals.

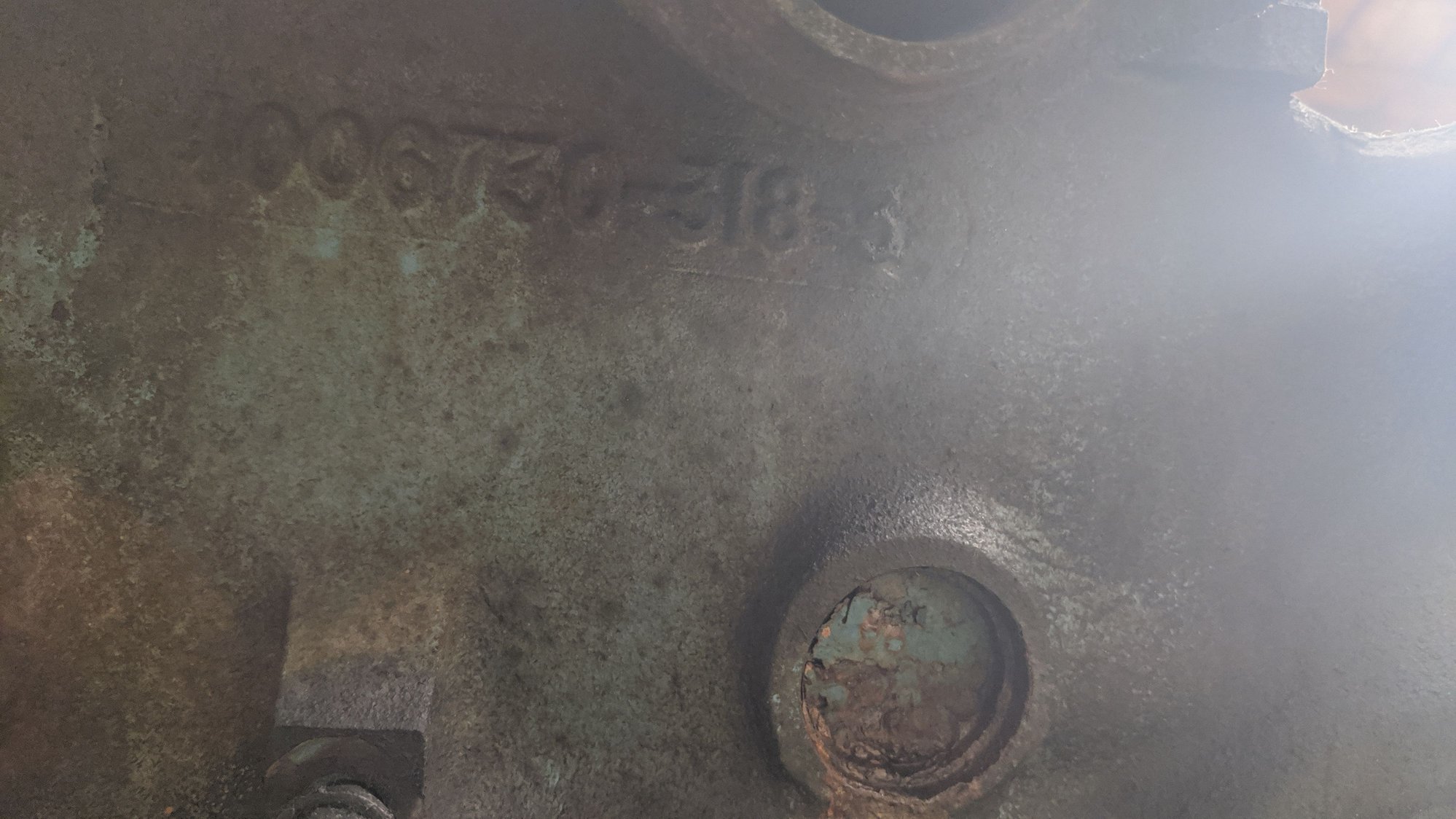

So here's the question I have, I'm building my old 86 jeep Comanche into a fun off-road rig so I started this journey when I aquired my Comanche about 4 years ago now from a guy that was moving south and needed some tires, long story short I got a running 86 MJ for a set of jeep tires and rims, anyways I've recently been getting into this project on it from stripping it down and patching things up here and there well time came to finnaly start picking new drive terrain so I went with a 318-3 out of what guy said was out of a 77 Plymouth fury with only 60,000 miles on the motor and the block matches the year but the 318-3 kinda makes me think that since it was a -3 that it would have came froma a HD truck like a 77 Ram charger instead of the fury. Any more info on that would be appreciated too I'll attach pictures of the number from the block.

Another question I also had was I of course want this to be a 4WD build with some power and have already been looking at t-cases too and picked up a Dana 300 double stick t-case but now I need to know what good transmissions would be good for a set up like this and is a setup like this even possible?

#2

Welcome. Lots of speculation about the -3 on forums, in the ‘60’s yes truck but had different cooling passages. I agree and my research showed it is just a casting series number as they changed worn tooling or introduced updates. Speculation from some say it will have a forged crank, not likely. My way is always take the oil pan off and have a look. There are a couple of things you should do if you plan to beat on this thing. Are you planning a full disassembly?

The following users liked this post:

Iowan (03-10-2020)

#4

Welcome. Lots of speculation about the -3 on forums, in the ‘60’s yes truck but had different cooling passages. I agree and my research showed it is just a casting series number as they changed worn tooling or introduced updates. Speculation from some say it will have a forged crank, not likely. My way is always take the oil pan off and have a look. There are a couple of things you should do if you plan to beat on this thing. Are you planning a full disassembly?

#5

There are some oil modifications you should do. I used a Comp Cam XE 252 H with great success in a heavy vehicle with lots of off idle pull, that whiplash may lose some down low with a big tire depending on axle ratio.

#6

And what would upgrades would you prefer and if any info on as to the carb that others may be using for off road .

#7

My first thought is a Holley 600cfm Double Pumper, not going 7000rpm. Many oil mods can be done and you can look up Guitar Jones oil mods at ForAbodiesonly, pictures and everything. Drilling out to 1/2" is not needed but the three I'd say are a must are:

1 - Smooth out oil pump discharge and main cap oil inlet.

2 - Additional holes drilled in oil filter adapter plate.

3 - Biggest must is long 10" long 9/32" drill from each main saddle up to right side oil galley. These are stepped drilled and restrictive to main bearings and I've read but not seen it myself where some were not drilled.

1 - Smooth out oil pump discharge and main cap oil inlet.

2 - Additional holes drilled in oil filter adapter plate.

3 - Biggest must is long 10" long 9/32" drill from each main saddle up to right side oil galley. These are stepped drilled and restrictive to main bearings and I've read but not seen it myself where some were not drilled.

#8

My first thought is a Holley 600cfm Double Pumper, not going 7000rpm. Many oil mods can be done and you can look up Guitar Jones oil mods at ForAbodiesonly, pictures and everything. Drilling out to 1/2" is not needed but the three I'd say are a must are:

1 - Smooth out oil pump discharge and main cap oil inlet.

2 - Additional holes drilled in oil filter adapter plate.

3 - Biggest must is long 10" long 9/32" drill from each main saddle up to right side oil galley. These are stepped drilled and restrictive to main bearings and I've read but not seen it myself where some were not drilled.

1 - Smooth out oil pump discharge and main cap oil inlet.

2 - Additional holes drilled in oil filter adapter plate.

3 - Biggest must is long 10" long 9/32" drill from each main saddle up to right side oil galley. These are stepped drilled and restrictive to main bearings and I've read but not seen it myself where some were not drilled.

Thread

Thread Starter

Forum

Replies

Last Post

jschrift

Engines, Exhaust and Fuel systems

3

12-14-2017 05:13 PM