383 Overheat Problem 1964 Polara

#1

383 Overheat Problem 1964 Polara

Well I am my wits end.

Details are a 1964 Polara 500, 383 cu. in. dual Quads, 482 lift cam, 3000 stall, 4:11 sure grip, electronic Ign, supposedly flat top pistons, 4 core downflow alum. radiator (originally had two core Alum. BE COOL cross flow prior to install of AC but it was too small I thinkl), fan shroud, electric pusher fan on AC condensor, 15" mechanical fan on engine side of radiator, 160 degree T-stat, new autometer mech. temp gage and the darn thing is still running hot.

The stock temp gage reads normal but --- the mech Autometer (and the Mopar mech gage before it) all show the engine is running about 210 and sometimes as much as 230 and climbing. The sending unit for the stock dash gage is in the same location relatively as the Autometer mechanical gage capillary unit. When running down the hiway the temp will come down to 190 but in town it gets hot with AC on or not (AC is a Gen 4 Vintage Air).

The only things I can speculate would cause this is a cracked head or head gasket problem. But no bubbles in radiator and no water in oil. I did not build the engine so don't know quallity of rebuild (roughly 11K on motor). I am wondering if it is possible the previous mechanic put a headgasket on backwards or upside down. Would this make the overheat problem like described? Also the Dist. is an electronic conversion but has a vacuum advance cannister on it. It is capped off (probably no vacuum with this cam). I wonder if the dist was recurved and has too much advance? Is this possible and may be contributing to the problem?

If I can't get this cured I am going to put in a 6.1 Gen lll HEMI in it this winter. Tired of messing with dual Quad setup and this overheat problem. Probably should have bought a Superbee or RR but really like the looks of this car. Been working on this one problem for over a year and just plain frustrated!! Thanks in Advance for any help or advice of how to fix this problem.

Randy

Details are a 1964 Polara 500, 383 cu. in. dual Quads, 482 lift cam, 3000 stall, 4:11 sure grip, electronic Ign, supposedly flat top pistons, 4 core downflow alum. radiator (originally had two core Alum. BE COOL cross flow prior to install of AC but it was too small I thinkl), fan shroud, electric pusher fan on AC condensor, 15" mechanical fan on engine side of radiator, 160 degree T-stat, new autometer mech. temp gage and the darn thing is still running hot.

The stock temp gage reads normal but --- the mech Autometer (and the Mopar mech gage before it) all show the engine is running about 210 and sometimes as much as 230 and climbing. The sending unit for the stock dash gage is in the same location relatively as the Autometer mechanical gage capillary unit. When running down the hiway the temp will come down to 190 but in town it gets hot with AC on or not (AC is a Gen 4 Vintage Air).

The only things I can speculate would cause this is a cracked head or head gasket problem. But no bubbles in radiator and no water in oil. I did not build the engine so don't know quallity of rebuild (roughly 11K on motor). I am wondering if it is possible the previous mechanic put a headgasket on backwards or upside down. Would this make the overheat problem like described? Also the Dist. is an electronic conversion but has a vacuum advance cannister on it. It is capped off (probably no vacuum with this cam). I wonder if the dist was recurved and has too much advance? Is this possible and may be contributing to the problem?

If I can't get this cured I am going to put in a 6.1 Gen lll HEMI in it this winter. Tired of messing with dual Quad setup and this overheat problem. Probably should have bought a Superbee or RR but really like the looks of this car. Been working on this one problem for over a year and just plain frustrated!! Thanks in Advance for any help or advice of how to fix this problem.

Randy

#2

Try couple of small things. First of 210 isn't that scary. A 15" mechanical fan is kinda small. Try to find a 19" seven blade fan with a heavy duty thermal fan clutch. Then try adding some water wetter to the radiator.

#3

230 is a little warm, but not "really." 190--210 is CERTAINLY not "overheating" especially if you are having "Kansas" weather. If it's warm/ hot there locally AND DRY, it's very difficult to obtain cooling. (Heat transfer works better on humid days than dry, even though humans don't feel so)

If it's not puking out the overflow, I'm not sure I'd worry too much.

Have you tried it without the electric? Some electrics are VERY poor and may RESTRICT air rather than help. Also, do you understand blade curvature? Some of these fans have either a poor blade design that is very inefficient, OR sometimes guys reverse them and run the blades curved the wrong direction, which kills airflow

What are you running for initial/ and total timing?

Look at this photo:

http://www.zeebuck.com/bimmers/tech/...ctricfan01.JPG

Notice that the "female cup" side of the blade is facing you. This blade, as shown, MUST turn to the left and pull air towards you. This means that if you now mount this fan in front, you cannot simply reverse the rotation. The blade will be extremely inefficient. You must turn the blade AROUND so that (if in front) the cup is to the radiator, and if this motor was mounted in front, the blade would turn to the RIGHT (and if viewed from the rear, would turn the SAME as if mounted in the rear, IE same as the first of this paragraph.

There are a few very poor designs which use straight blades, and "don't work" in EITHER direction. I would say that if your fan?(S) pull less than 20A per motor, they are worthless. It takes a HELL of a lot of power to move air

How 'bout your mechanical fan? Flex? Aluminum? Try an old school STEEL blade or a temp controlled clutch fan.

If it's not puking out the overflow, I'm not sure I'd worry too much.

Have you tried it without the electric? Some electrics are VERY poor and may RESTRICT air rather than help. Also, do you understand blade curvature? Some of these fans have either a poor blade design that is very inefficient, OR sometimes guys reverse them and run the blades curved the wrong direction, which kills airflow

What are you running for initial/ and total timing?

Look at this photo:

http://www.zeebuck.com/bimmers/tech/...ctricfan01.JPG

Notice that the "female cup" side of the blade is facing you. This blade, as shown, MUST turn to the left and pull air towards you. This means that if you now mount this fan in front, you cannot simply reverse the rotation. The blade will be extremely inefficient. You must turn the blade AROUND so that (if in front) the cup is to the radiator, and if this motor was mounted in front, the blade would turn to the RIGHT (and if viewed from the rear, would turn the SAME as if mounted in the rear, IE same as the first of this paragraph.

There are a few very poor designs which use straight blades, and "don't work" in EITHER direction. I would say that if your fan?(S) pull less than 20A per motor, they are worthless. It takes a HELL of a lot of power to move air

How 'bout your mechanical fan? Flex? Aluminum? Try an old school STEEL blade or a temp controlled clutch fan.

Last edited by 440roadrunner; 06-11-2012 at 10:59 AM.

The following users liked this post:

SSMOPAR (06-15-2012)

#4

I would also like to interject a thought... Why a 160 thermostat? I would go to a 180. Once 160 temp is achieved unless its really COLD outside (Ambient air temp) it will never even think of trying to close to slow/stop coolant flow for its cooling "cycle" in the radiator... I have known several ppl that have TRIED to use a 160 on the street and it ends up running 'hottter' than with a 180. But Eric and 440 are correct, 210 isnt 'hot' and 230 is a little warm but not motor melting/damaging hot.... Also I would ditch the electric altogether cant figure why you would run both an elec AND mechanical fan @ once... Largest mech fan you can fit, with a proper fan shroud, CORRECT T-stat and you should see no overheating unless you have a circulation problem, which is another thing altogether... As 440 stated if the electric isnt pulling @ least 20 amps, its not moving any air... (dont think i am saying that you are dumb, but a thought just occurred to me... the fans ARE trying to move the air in the SAME direction right?)

#5

Thanks to all. I have checked the Elecric fan and it seems to be pulling the air through the AC condensor correctly. The mechanical engine fan was changed from a 17 " steel 7 blade flex fan to a 15" non flex fan due to clearance problem with lower crank 4 groove pulley and the new radiator core (New 4 core is thicker thus less clearance). I have recently installed a shroud for the engine fan. Direction of flow on both fans seems to be correct. The electric fan (only 0ne, 16") is mounted on the AC condensor core and faces the engine. It is mainly to cool the condensor when running the AC. 230 degree would be acceptable but the temp will climb beyond that in slow traffic (i.e. parade stuff, stop and go, etc.). I had a 180 Tstat in before and it did the same. The electric fan switch is set at 190 degree and is in the radiator where the cool water is fed to the engine (think radiator drain opening). It does not come on until mechanical water temp gage reads 220. So I would surmise the water coming out of the radiator is below 190 degrees even though gage reads 220. The water temp gage is mounted on the upper part of the engine and is reading the water temp going to the radiator out of the heads and block. I do not know the intial advance or total curve in Dist as yet. That's next. I will try the water wetter additive also. The radiator does not puke and I have an overflow catch can.

Please keep in mind I am trying to fix a car that has had a few Bubba's work on in the past. If you all think the temp is okay I will drive it and quit worrying about it. After all, if it blows that gives me a good excuse to put in a new Gen lll HEMI. I guess what worrys me is that the stock gage reads normal and the aftermarket mechanical gage shows what I thought was a high temp and they are both located within a couple of inches of each other in the same cavity on the engine. I sure don't want to get out in the middle of "You can't get there from here, Kansas" and have a breakdown. Got a bad heart and the heat would surely do me in. At what temp should I be concerned?? I have never had a MOPAR or any other brand that ran over 200 degrees. Guess I have been lucky but then I rebuilt all the other engines myself.

Please keep in mind I am trying to fix a car that has had a few Bubba's work on in the past. If you all think the temp is okay I will drive it and quit worrying about it. After all, if it blows that gives me a good excuse to put in a new Gen lll HEMI. I guess what worrys me is that the stock gage reads normal and the aftermarket mechanical gage shows what I thought was a high temp and they are both located within a couple of inches of each other in the same cavity on the engine. I sure don't want to get out in the middle of "You can't get there from here, Kansas" and have a breakdown. Got a bad heart and the heat would surely do me in. At what temp should I be concerned?? I have never had a MOPAR or any other brand that ran over 200 degrees. Guess I have been lucky but then I rebuilt all the other engines myself.

#6

Thanks to all. I have checked the Elecric fan and it seems to be pulling the air through the AC condensor correctly. The mechanical engine fan was changed from a 17 " steel 7 blade flex fan to a 15" non flex fan due to clearance problem with lower crank 4 groove pulley and the new radiator core (New 4 core is thicker thus less clearance). I have recently installed a shroud for the engine fan. Direction of flow on both fans seems to be correct. The electric fan (only 0ne, 16") is mounted on the AC condensor core and faces the engine. It is mainly to cool the condensor when running the AC. 230 degree would be acceptable but the temp will climb beyond that in slow traffic (i.e. parade stuff, stop and go, etc.). I had a 180 Tstat in before and it did the same. The electric fan switch is set at 190 degree and is in the radiator where the cool water is fed to the engine (think radiator drain opening). It does not come on until mechanical water temp gage reads 220. So I would surmise the water coming out of the radiator is below 190 degrees even though gage reads 220. The water temp gage is mounted on the upper part of the engine and is reading the water temp going to the radiator out of the heads and block. I do not know the intial advance or total curve in Dist as yet. That's next. I will try the water wetter additive also. The radiator does not puke and I have an overflow catch can.

Please keep in mind I am trying to fix a car that has had a few Bubba's work on in the past. If you all think the temp is okay I will drive it and quit worrying about it. After all, if it blows that gives me a good excuse to put in a new Gen lll HEMI. I guess what worrys me is that the stock gage reads normal and the aftermarket mechanical gage shows what I thought was a high temp and they are both located within a couple of inches of each other in the same cavity on the engine. I sure don't want to get out in the middle of "You can't get there from here, Kansas" and have a breakdown. Got a bad heart and the heat would surely do me in. At what temp should I be concerned?? I have never had a MOPAR or any other brand that ran over 200 degrees. Guess I have been lucky but then I rebuilt all the other engines myself.

Please keep in mind I am trying to fix a car that has had a few Bubba's work on in the past. If you all think the temp is okay I will drive it and quit worrying about it. After all, if it blows that gives me a good excuse to put in a new Gen lll HEMI. I guess what worrys me is that the stock gage reads normal and the aftermarket mechanical gage shows what I thought was a high temp and they are both located within a couple of inches of each other in the same cavity on the engine. I sure don't want to get out in the middle of "You can't get there from here, Kansas" and have a breakdown. Got a bad heart and the heat would surely do me in. At what temp should I be concerned?? I have never had a MOPAR or any other brand that ran over 200 degrees. Guess I have been lucky but then I rebuilt all the other engines myself.

#7

The electric fan (only 0ne, 16") is mounted on the AC condenser core and faces the engine. It is mainly to cool the condenser when running the AC.

230 degree would be acceptable but the temp will climb beyond that in slow traffic (i.e. parade stuff, stop and go, etc.).

I had a 180 Tstat in before and it did the same. The electric fan switch is set at 190 degree and is in the radiator where the cool water is fed to the engine (think radiator drain opening). It does not come on until mechanical water temp gage reads 220.

So I would surmise the water coming out of the radiator is below 190 degrees even though gage reads 220. The water temp gage is mounted on the upper part of the engine and is reading the water temp going to the radiator out of the heads and block.

The radiator does not puke and I have an overflow catch can.

I guess what worrys me is that the stock gage reads normal and the aftermarket mechanical gage shows what I thought was a high temp and they are both located within a couple of inches of each other in the same cavity on the engine.

I sure don't want to get out in the middle of "You can't get there from here, Kansas" and have a breakdown. Got a bad heart and the heat would surely do me in. At what temp should I be concerned?? I have never had a MOPAR or any other brand that ran over 200 degrees. Guess I have been lucky but then I rebuilt all the other engines myself.

The following users liked this post:

SSMOPAR (06-12-2012)

#8

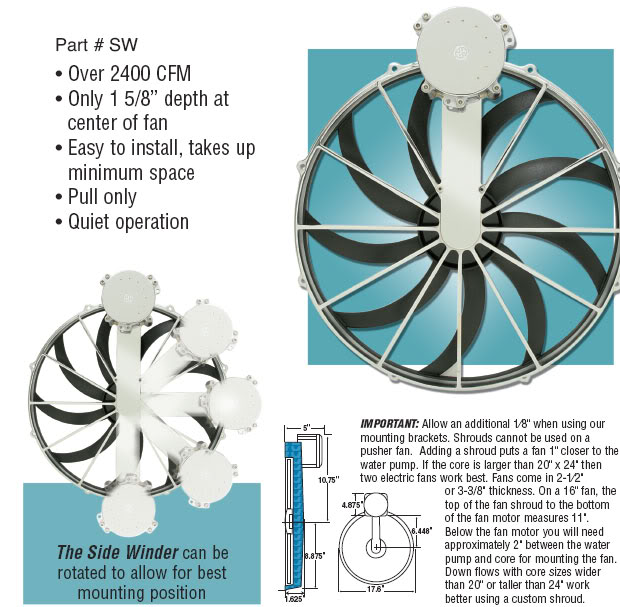

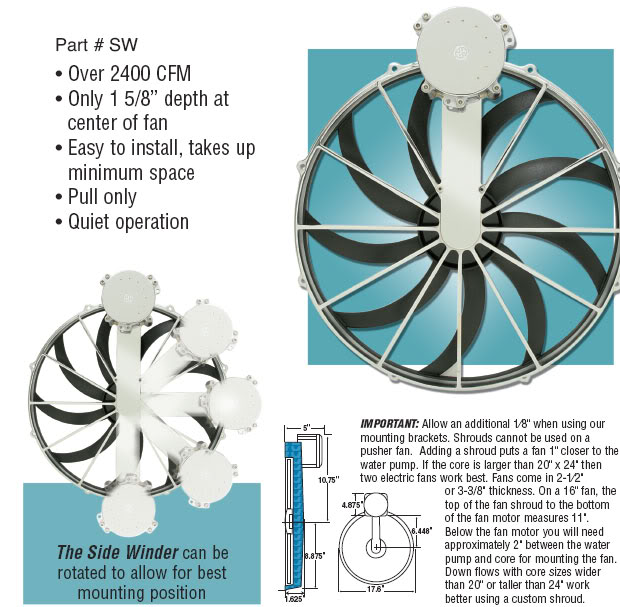

You might even try one of these sidewinder fans as a puller and ditch the mechanical fan.

http://www.mattsonscustomradiator.com/side-winder.html

http://www.mattsonscustomradiator.com/side-winder.html

#9

ok. I will try to answer all the questions.

#(Whoa Whoa WHOA now.... PULLING air thru the a/c condenser?? WHERE pray tell it it mounted? In front of radiator? And fan mounted on outside of it? (grill side))

It is mounted on the grill side of the conmdensor and it is a pusher type.

IT helps bring down the temp when it comes on (190 degrees)while AC is running. AC condensor is in front of the radiator as it should be.

#(Unnecessary but ok if it makes you a happy camper...)

See above as to why I did this.

# (How hard is it to bring down temp once its climbed over the 230 mark? A quick higher speed run, just park it and wait or what?)

Not hard at all. Once in the wind at over 30 MPH for about a mile it brings down temp pretty quickly to 190 or so.

#(Ummm And you see nothing wrong here? I would strongly suspect the temp gauge... Not that the fan switch is accurate BUT another gauge wouldnt be out of the question)

That was my first thought actually and I just spent about $175 on a Cobalt Autometer (Mech) gage to replace the MOPAR performance (Mech) gage I suspected to be bad. The temp gage reads the same as before. Suspect the OEM gage is off or OEM sender is bad.

#( Thats a BIG possibility. The temp gauge is i am assuming mounted in the water 'cross-over' area of the intake near the t-stat? ( not familiar with the 383 really)

No on 383 the gages senders mount in the water pump housing area on pass side of block near the heater hose outlets.

The rest of the questions have basically been already answered BUT:

I did check timing and it was 6 degrees to far advanced. Set it back to 10 degrees and it seems to help a little. Also added a quart of that water wetter but didn't real see any difference.

BREMERERIC:

I really like that sidewinder fan. Wish I had seen that before I bought a new shroud and stuff. Still might give it a whirl if I can't get more airflow. Thanks.

#(Whoa Whoa WHOA now.... PULLING air thru the a/c condenser?? WHERE pray tell it it mounted? In front of radiator? And fan mounted on outside of it? (grill side))

It is mounted on the grill side of the conmdensor and it is a pusher type.

IT helps bring down the temp when it comes on (190 degrees)while AC is running. AC condensor is in front of the radiator as it should be.

#(Unnecessary but ok if it makes you a happy camper...)

See above as to why I did this.

# (How hard is it to bring down temp once its climbed over the 230 mark? A quick higher speed run, just park it and wait or what?)

Not hard at all. Once in the wind at over 30 MPH for about a mile it brings down temp pretty quickly to 190 or so.

#(Ummm And you see nothing wrong here? I would strongly suspect the temp gauge... Not that the fan switch is accurate BUT another gauge wouldnt be out of the question)

That was my first thought actually and I just spent about $175 on a Cobalt Autometer (Mech) gage to replace the MOPAR performance (Mech) gage I suspected to be bad. The temp gage reads the same as before. Suspect the OEM gage is off or OEM sender is bad.

#( Thats a BIG possibility. The temp gauge is i am assuming mounted in the water 'cross-over' area of the intake near the t-stat? ( not familiar with the 383 really)

No on 383 the gages senders mount in the water pump housing area on pass side of block near the heater hose outlets.

The rest of the questions have basically been already answered BUT:

I did check timing and it was 6 degrees to far advanced. Set it back to 10 degrees and it seems to help a little. Also added a quart of that water wetter but didn't real see any difference.

BREMERERIC:

I really like that sidewinder fan. Wish I had seen that before I bought a new shroud and stuff. Still might give it a whirl if I can't get more airflow. Thanks.

#10

WOW 175 for a water temp gauge? dunno where ya go to buy but holy cow... I am confused as to how if its a mechanical gauge you used the OEM sender? I have never seen a 2 piece style mechanical temp gauge.. they have a capillary tube and sensing 'probe' on the end. What is the gauge no. you got? If it hooks up by wire its an electric gauge and then the statement about the OEM sender makes sense to ME...the auto meter water temp gauges i looked @ on Jegs werent that expensive, not unless shipping is close to 20 bux, which I can see, altho overpriced in my opinion...

2 5/8" Elec gauge 165.99 so ok, 108.99 for the mechanical 2 5/8ths"...

2 5/8" Elec gauge 165.99 so ok, 108.99 for the mechanical 2 5/8ths"...

Last edited by MrOldart2U; 06-14-2012 at 08:29 PM. Reason: dug a lil deeper on pricing

#11

To clarify the gage question-- It is a Cobalt 2 5/8 mechanical gage and I also bought a matching 2 5/8 Cobalt oil mechanical oil pressure gage. (Couldn't have two different looking gages in the car.) And yes they are expensive.

You are confusing two different gages, one the stock dash gage (electrical sending unit) and the other is the Cobalt mech gage.

As for the electrical sender -- it is for the stock Dash gage and has nothing to do with the mechanical temp gage recently installed. I don't know what gages you were revieiwing at JEGS but I am sure they are not full sweep type. And sure you can find cheaper ones. Heck, JC Whitney just about gives them away. But over the many years I have been messing with old cars I found you usually get what you pay for. Cheap gages will cost you an engine or at least you will be replacing them within the next year or two. I just don't like to do things over. A wise man once told me "If you don't have the time to do it right the first time, when will you have time to do it over". Also if you were familiar with the stock electrical sending unit in this 383 engine, you would know that the aftermarket mechanical capillary tube can not be screwed into that location. The electrical sending unit opening is way too small (at least on this 383).

But the good news is that I think I have got the answer. The temp will not climb above 195 running down the road even when it is 94 degrees ambient. So, what I have is an airflow problem. I am going to chuck up the 4 groove crank pulley and remove the outside non-used pulley groove off the darn thing so I can re-install the 18" steel flex fan that was on it before. In addition, I am moving the electrical pusher fan temp control switch fromn the bottom of the radiator (cool side) to the top inlet hose (hot side). I will also install a new fan switch which is adjustable from 160 to 220. Additionally I am going to equip the switch with a manual override controlled from the drivers seat.

Oh, and the old gages I removed are 2 5/8 MOPAR performance gages, (both mechanical) and are the full sweep type. They are black faced and I will probably take them to a swap meet along with the soon to be replace dual quad setup and the old heater and ducting. Thanks for your input.

You are confusing two different gages, one the stock dash gage (electrical sending unit) and the other is the Cobalt mech gage.

As for the electrical sender -- it is for the stock Dash gage and has nothing to do with the mechanical temp gage recently installed. I don't know what gages you were revieiwing at JEGS but I am sure they are not full sweep type. And sure you can find cheaper ones. Heck, JC Whitney just about gives them away. But over the many years I have been messing with old cars I found you usually get what you pay for. Cheap gages will cost you an engine or at least you will be replacing them within the next year or two. I just don't like to do things over. A wise man once told me "If you don't have the time to do it right the first time, when will you have time to do it over". Also if you were familiar with the stock electrical sending unit in this 383 engine, you would know that the aftermarket mechanical capillary tube can not be screwed into that location. The electrical sending unit opening is way too small (at least on this 383).

But the good news is that I think I have got the answer. The temp will not climb above 195 running down the road even when it is 94 degrees ambient. So, what I have is an airflow problem. I am going to chuck up the 4 groove crank pulley and remove the outside non-used pulley groove off the darn thing so I can re-install the 18" steel flex fan that was on it before. In addition, I am moving the electrical pusher fan temp control switch fromn the bottom of the radiator (cool side) to the top inlet hose (hot side). I will also install a new fan switch which is adjustable from 160 to 220. Additionally I am going to equip the switch with a manual override controlled from the drivers seat.

Oh, and the old gages I removed are 2 5/8 MOPAR performance gages, (both mechanical) and are the full sweep type. They are black faced and I will probably take them to a swap meet along with the soon to be replace dual quad setup and the old heater and ducting. Thanks for your input.

#12

Late to the game but let me add my 2 cents. Forgive me if some of this was answered, I skimmed the above... And you got answers from some of the forums most experienced folks so your heading in the right direction already.

The car cools down nicely when you drive it correct? So the system works so long as air passes thru the radiator.

Do this test for me. Disconnect the electric pusher fan and start the car. Then take a piece of newspaper and tell us if the mech fan is creating enough pull to suck the paper to the radiator.

If it doesn't you have your problem. Your mech fan is blowing hot air on your engine instead of pulling fresh air thru the radiator.

You can add spacers to bring it closer to the radiator. And retest.

OR

I have used ( and currently use ) the Lincoln Mark 7 and Taurus E fan on several hard to cool projects. They run about 50 bucks at the junk yard and have their own shroud. And two speeds. The high speed was too much cooling for my needs. It over cooled. They pull over 3000cfm. The down side is they need a VERY heavy duty relay. That doubles the price unless you have one already. You can add an adjustable sending unit trigger for low speed and have the AC trigger the high speed if she just runs hot.

Ive used them on autocross, rock crawlers, tow applications. Never had an issue.

Only thing else I would add is dont plumb the tranny thru the radiator. And set the current electric fan to activate when you call for AC. Not ten degrees over tstat opening range.

The car cools down nicely when you drive it correct? So the system works so long as air passes thru the radiator.

Do this test for me. Disconnect the electric pusher fan and start the car. Then take a piece of newspaper and tell us if the mech fan is creating enough pull to suck the paper to the radiator.

If it doesn't you have your problem. Your mech fan is blowing hot air on your engine instead of pulling fresh air thru the radiator.

You can add spacers to bring it closer to the radiator. And retest.

OR

I have used ( and currently use ) the Lincoln Mark 7 and Taurus E fan on several hard to cool projects. They run about 50 bucks at the junk yard and have their own shroud. And two speeds. The high speed was too much cooling for my needs. It over cooled. They pull over 3000cfm. The down side is they need a VERY heavy duty relay. That doubles the price unless you have one already. You can add an adjustable sending unit trigger for low speed and have the AC trigger the high speed if she just runs hot.

Ive used them on autocross, rock crawlers, tow applications. Never had an issue.

Only thing else I would add is dont plumb the tranny thru the radiator. And set the current electric fan to activate when you call for AC. Not ten degrees over tstat opening range.

#13

Finally got the problem fixed. Did all that I was going to do as stated in previous post. Also redid the shroud to help with airflow. Did July 4th parade in 104 temp at barely over an idle and never got above 200 degrees. Ran all the way home with AC on and it was only around 185 at highway speed. Thanks to all for the help and advice. Oh there was two other things that I found wrong. The engine was sitting at 12 degrees down in the back which made the fan sit unsquare with radiator. Inserted a shim under trans mount and raised the motor 8 degrees. Fan is now evenly spaced 1" from radiator and engine has the correct 3 degree tilt toward year. Driveshaft angle is now correct. Second thing was the timing was set at 16 degrees advanced. Reset at 10 and the car is smoother and just as peppy. I swear Bubba used to own this car, LOL.

#14

I assume the vacuum advance is disconnected or at least connected to ported vacuum not manifold , the Jag clutch fan fits the older B bodies , I use an 18 Flex-a-lite fan on the jag clutch for best results . Another thing to look for is a spring inside the lower rad hose to prevent the hose from collapsing .

Glad you got it solved !

Glad you got it solved !

Thread

Thread Starter

Forum

Replies

Last Post

cognitive77

Mopar Classifieds

2

01-13-2009 02:13 PM