12V Source Confusion

#1

12V Source Confusion

Hello again. The rebuild is finally complete with the exception of needed wiring. I am reluctant to connect the battery until i figure out all the new wiring. Some add-ons are calling for connection to the battery and others are calling for connection to the ignition or a switched 12V source. In the meantime, I am thinking the main post on the Starter Relay, is a good place to attach those new 12 gauge engine compartment circuits requiring a switched 12V source, assuming the main post is only live when the yellow 12V wire is hitting the relay with juice from the ignition. Am I right or wrong? I am not sure were I should go for the battery (I am assuming they mean a constant 12V source), as it is back in the trunk and running juice forward to the starter via 1/2 inch battery cables. I am thinking I should install a power distribution block off the starter for current and future needs under the hood. Does this sound about right... or am I missing something obvious to those seasoned electronics wizards out there?:banghead:

Last edited by 68GTX440; 11-01-2013 at 06:58 PM. Reason: tweak text

#4

ok, let me see if I understand your comments. The main post on Starter Motor is always HOT. I get this, and I think you meant the Starter Solenoid wires leading from the Starter Relay are only HOT during cranking. I remain confused over the on/off logic associated to the main post situated on the Starter Relay.

#6

When the solenoid is energized it moves and mechanically slides the gear into the flywheel and connects power from the main post to the motor making it turn. It is basically a large switch inside.

Running a cable from that post to a distribution block would be OK, if you search battery relocate diagram you'll find plenty of examples. Look at a main relay, be cautious how you wire to the alternator and don't forget fusible links.

Running a cable from that post to a distribution block would be OK, if you search battery relocate diagram you'll find plenty of examples. Look at a main relay, be cautious how you wire to the alternator and don't forget fusible links.

#7

ok, let me see if I understand your comments. The main post on Starter Motor is always HOT. I get this, and I think you meant the Starter Solenoid wires leading from the Starter Relay are only HOT during cranking. I remain confused over the on/off logic associated to the main post situated on the Starter Relay.

The following users liked this post:

68GTX440 (11-01-2013)

#8

Thank you for clarifying the on/off status of nutted post on the Starter Relay. This certainly changes things for me, as I was intending to target this location for all new 12 Volt switched circuits. It looked heavy enough to do the job, if proven to be HOT during ignition ON. My new loads include: a new Holley carb's (electronic choke) (+)fused; a vacuum Pump c/w dedicated relay, also fused; a transmission cooler fan c/w dedicated relay, also fused; and last but not least a Flex-a-lite radiator cooling fan c/w dedicated relay, also fused. It is suggested the rad fan goes to the battery, if you want it running after the ignition has been turned off, but I fail to see the need for the fan running after walking away from the vehicle. I didn't think it would be wise to run separate 12 gauge circuits to each of the 3 relays from the fuse panel under the dash, so I was looking for a switched 12V source engine side, other than the horn relay, but so far it looks like there isn't one. I am leaning towards a new fuse panel engine side, that I assume must be powered by the alternator and not puppy dogged to the original fuse panel, as I suspect that doing so would cause excessive demand upon the original fuse panel wiring. Done correctly, I should be able to properly distribute switched power to all relays. I have seen where additional relays have been powered off the (+) horn relay. It looks to be the simplest solution for powering the relays and perhaps all that is really needed, but as I understand it, the problem remains in supplying switched power - to each of the fans. Would it be ok to power all the above noted fan systems off my upgraded alternator, if using fused links in each circuit beyond the alternator? Any other suggestions for a better solution?

Last edited by 68GTX440; 11-01-2013 at 09:54 PM.

#9

I think an auxiliary switch panel in the cockpit would be a good way to switch the "keyed" items without hacking the factory wiring up. Then maybe an auxiliary fuse block/relay station (a'la Painless etc) under hood somewhere convenient, and the "always hot" loads could come off this too. If it were me doing it, I would feed the new fuse panel off the large starter lug on the relay with a fusible link. Check out Summit Racing for the electrical items I mentioned above, lots of helpful stuff there. Check out PRF-70207.

Last edited by Mr.4spd; 11-02-2013 at 10:04 AM.

The following users liked this post:

68GTX440 (11-02-2013)

#10

You are adding "quite a bit of stuff" and if the wiring is pretty much factory except for the trunk mod, the factory wiring is not up to the task

The weak points ESPECIALLY when adding a lot of extra loads is the bulkhead connector, the ammeter, the fuse link on older cars, and too small wiring from the ammeter and from the starter relay

Please read this excellent article which points up the problems with the above

http://www.madelectrical.com/electri...p-gauges.shtml

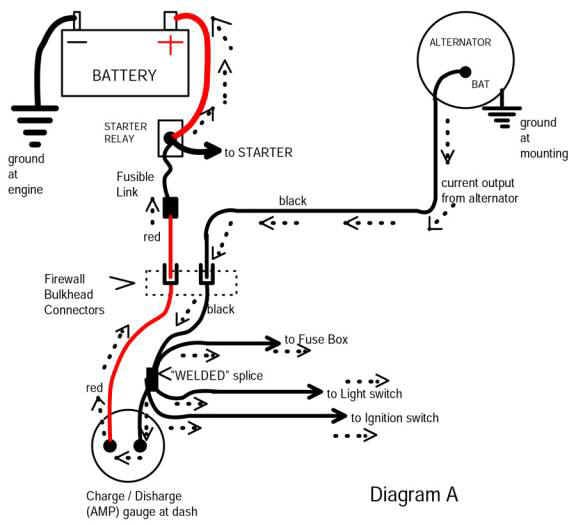

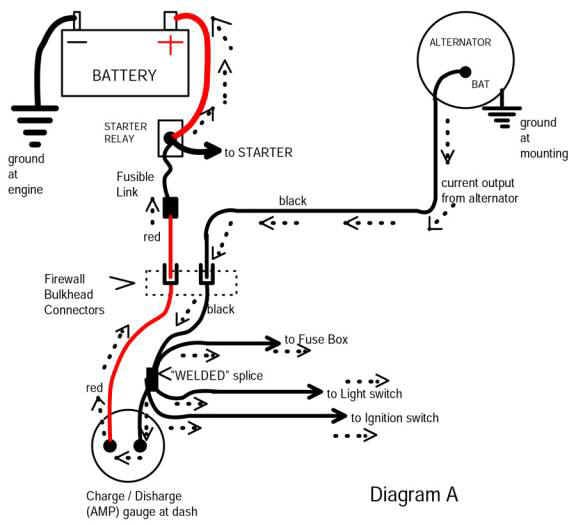

The simplified wiring diagram down the page tells part of the story, follow along

Starting at battery positive, now in the trunk, you probably have a large cable going to the starter, then back up to the starter relay. Electrically, then "we are at" the starter relay.

From the relay we go through the fuse link, possibly too small

The red continues through the bulkhead connector ANOTHER weak point, and onwards to the ammeter YET ANOTHER weak point, both the wire ends, the ammeter itself

Then the black returns BACK through the bulkhead.......another weak point on the way to finally, the alternator.

Heavier loads and heavier alternators TAX and "fail" these points

Using relays under the hood to supply added loads OR FOR THAT MATTER existing loads such as ignition and head lights RELIEVES strain on this stuff.

(Voltage drop through the system causes overcharging because the regulator "sees" reduced voltage.)

This thread here at FABO might give you some ideas .......if you wish.......on how to build a voltmeter right into your dash. Please read all three pages, as it covers different types of dash clusters.

http://www.forabodiesonly.com/mopar/...d.php?t=119480

The weak points ESPECIALLY when adding a lot of extra loads is the bulkhead connector, the ammeter, the fuse link on older cars, and too small wiring from the ammeter and from the starter relay

Please read this excellent article which points up the problems with the above

http://www.madelectrical.com/electri...p-gauges.shtml

The simplified wiring diagram down the page tells part of the story, follow along

Starting at battery positive, now in the trunk, you probably have a large cable going to the starter, then back up to the starter relay. Electrically, then "we are at" the starter relay.

From the relay we go through the fuse link, possibly too small

The red continues through the bulkhead connector ANOTHER weak point, and onwards to the ammeter YET ANOTHER weak point, both the wire ends, the ammeter itself

Then the black returns BACK through the bulkhead.......another weak point on the way to finally, the alternator.

Heavier loads and heavier alternators TAX and "fail" these points

Using relays under the hood to supply added loads OR FOR THAT MATTER existing loads such as ignition and head lights RELIEVES strain on this stuff.

(Voltage drop through the system causes overcharging because the regulator "sees" reduced voltage.)

This thread here at FABO might give you some ideas .......if you wish.......on how to build a voltmeter right into your dash. Please read all three pages, as it covers different types of dash clusters.

http://www.forabodiesonly.com/mopar/...d.php?t=119480

The following users liked this post:

68GTX440 (11-02-2013)

#11

I can't thank you enough for your helpful comments. At the moment, I am overwhelmed with the electrical side of this rebuild. You are right! I am adding a lot of new stuff. During my prior research on updating mopar electronics, I read all of the articles you mentioned. To give you a better idea of what I am dealing with: the battery relocation had already been done before I bought the car over 20 years ago. I had given the car to my brother for about 6 years, during which time he made several changes to the wiring. He was an electronics wiz. One of those rare guys who can fix pretty much anything on the planet, but sadly he died a few years ago, leaving me to figure out what now goes where. I know he choked after being broken down on the side of the highway once to many times, so he removed the bulkhead connection and soldered up all the wires eliminating the problem. I know he also bi-passed the ammeter, as the wires are now off it and connected together under the dash. When disconnecting all the engine compartment wiring during this latest rebuild, I was not smart enough to label all the wires. I did some, but not all of em. Now, I wished I had labelled them ALL. Being the old greaser that I am, my memory just isn't what it used to be! My problems seem ten fold, in that I am not introducing just one new item to the circuit, rather a whole bunch all at the same time. So far, I have tried to focus on just one problem at a time but repeatedly, I have had to rethink what I am doing - because I did not design a detailed schematic including all of the modifications beforehand. As I have had to work alone on this project, I made up a 10 foot long wire with an alligator clip at each end. I used this wire to help establish continuity of unknown wires leading under the dash or elsewhere in the wiring harness, some of which have changed colours, or been interrupted by non stock fusable links etc. etc. To date, some remain unidentified. A frustrating situation! In the meantime, after reading all the comments on this thread, I isolated the 'Starter Relay' and put 12 volts across the ignition pin, hoping to confirm in my mind - the larger threaded post is in fact HOT only during the ignition's START position and that 12 Volts would be passed through the two central solenoid output pins of the relay. Test failed. I have no idea why. Perhaps because there is nothing currently connected to 'C' pin on the relay, Now that I think about it, I'm not sure there ever was a wire connected to that pin. In addition, I have yet to complete the fun job of finding a way to hook up heavy I/O battery cable still laying under the car - to the new Mini starter currently buried deep within the confines of a new set of Doug's headers. Sorry, must dash.... will add more comments later.

Last edited by 68GTX440; 11-02-2013 at 09:05 PM.

#12

This might help... Got it from My Mopar.Com.....

http://www.mymopar.com/downloads/196...dRunneFull.pdf

http://www.mymopar.com/downloads/196...dRunneFull.pdf

The following users liked this post:

68GTX440 (11-02-2013)

#13

Thank-you very much for the wiring diagrams. They will be most helpful, not only during this phase of the rebuild, but also later when I revisit old issues within the central console, getting courtesy lamps to illuminate when either door is opened.

A job that was driving me crazy earlier, until I discovered that a bulb having the wrong pin locations had been inserted - effectively creating all kinds of grief.

So I must now refocus and get this baby flashed up, before all the break in lube drains into the pan...

I went down to the only electronics vendor in town, hoping to look at: a few different switch systems, perhaps some power distribution blocks and/or fuse blocks with it in mind to get a better read on what combo would work the best for me, but unfortunately they were out of stock and uninformed on this topic.

Let me see if I understand the remaining issues correctly.

1) I should avoid any additional load upon existing circuits, so must figure out a way to create a new circuit engine side, to control all the new electronics.

2) I have an updated (2 field) alternator currently monitored by an older single field (race only) regulator. For this to work, I have grounded the farthest field in a clockwise direction from the alternator's (+) terminal to it's grounding pin

on the edge of casing. I assume I must also connect this same grounding pin using updated (8 gauge wire) to nearby vehicle ground, perhaps a little over kill here, I'm not sure, but better safe than sorry. (As far as the old regulator goes, I will likely replace it later with a new double field unit, complete with the 2nd field field wiring mods where required, but for now, I have more than enough trouble getting what I have to work properly.

3) Given the Ammetre has already been bi-passed, I don't wish to address any wiring under the dash, unless it is absolutely necessary. So as to have some clue what is going on with the charging system, I bought a new Volt meter that I have yet to wire into the system. Hopefully... I get that right.

4) I have installed an MSD (Ready-to-Run) distributor and a MSD Blaster Coil whose instructions advised me to bi-pass the coil's original resistor. I elected to replace the old crappy looking resistor, with a new resistor supplied within the MSD coil package, leaving a resistor in the circuit, but also bi-passing it as per the instructions. (I'm not sure if the resistor now serves any useful purpose, nor do I know if it has the same resistance as did the original unit, but what I've done is done. Have my fingers crossed and hoping it works.

5) I installed a new Holley 800+ CFM carb c/w an electronic choke earlier that is currently wired through a 15 AMP fuse and into an (ignition) source beneath the dash. I am thinking it would be best to relocate this load to the suggested switchable 12V source @ fuse block within the new circuit engine side.

6) I installed a new kick-butt Vacuum Pump and reservoir back-up system to address the loss of vacuum, created by the newly installed Hughes Whiplash cam. It comes with a 40 AMP relay that calls for a switchable 12V source. I believe it also suggests the pump's (+) circuit be protected using a fuse. At the moment, I can't remember what size of a fuse, but hopefully - I can find the instructions on that issue later. I am guessing 20-30 AMP.

7) I installed a new Perma-Cool Transmission Cooler that reportedly does not require a relay. The associated in line sensor unit, requires a switchable 12V source, that when reaching the appropriate temperature, activates the fan, which calls for protection via inclusion of a 30 AMP fuse on the (-) side of the fan circuit before attaching to ground. I know not why the negative side of this fan circuit must be fused. I thought the fuse always goes on the (+) side of a circuit, but then what do I know...

8) I installed a new Flex-a-lite High Performance X-flow radiator c/w a pusher fan & shroud system and a 40 AMP relay, whose instructions call for either a switchable 12V source or (+) battery depending on whether or not you want the fan to run after the engine has been shut down. In either case, power in this circuit goes through an included circuit breaker. Relay action is dictated by an in line electronic sensor installed within the radiator (IN) hose.

9) A bunch of other mods were completed outside the topic of this thread.

10) So what remains, is still some confusion over exactly what new wiring system I should build to best furnish switched 12V power to all new relays

and the described loads.

a) I am liking the idea of installing a new fuse block on inner driver side fender well, just ahead of the original battery location, now in the trunk.

I could easily run a new 6 gauge c/w fuseable link to the fuse block (IN)

at that location, from which short 10 gauge runs could be made to near

by relays. I have no idea what fuse block would be best. I am thinking it

should be waterproof and have an on board relay to isolate not only the

block, but all subsequent circuits created therein from existing harness.

b) I am unsure if I also require a power distribution block... example: 6

gauge 1 (IN) via fuseable link from (+) starter motor with 10 gauge 4-5

(OUT) to satisfy those power demands on the load side of each relay or

if this can be achieved upon selection of the correct fuse block capable

of doing the same thing?

c) Another alternative, is going with a bank of non fused switches on

the dash, given that all circuits will be protected via fuses elsewhere.

I am guessing this option would work well with the power distribution

block design mentioned above, assuming I would find some enjoyment

in playing with switches (ON/ON/ON/ON) & OFF/OFF/OFF/OFF), likely

several times per trip. Hummm. Gotta be an easier way to do this!

I think I will call Summit Racing in the morning and actually kick some of

this same stuff around with an electronics tech.. in hopes of identifying

product(s) they may have in stock to best resolve current wiring needs.

Am I on the right track? What are your thoughts?

Sorry it's late and I am done for the night.

A job that was driving me crazy earlier, until I discovered that a bulb having the wrong pin locations had been inserted - effectively creating all kinds of grief.

So I must now refocus and get this baby flashed up, before all the break in lube drains into the pan...

I went down to the only electronics vendor in town, hoping to look at: a few different switch systems, perhaps some power distribution blocks and/or fuse blocks with it in mind to get a better read on what combo would work the best for me, but unfortunately they were out of stock and uninformed on this topic.

Let me see if I understand the remaining issues correctly.

1) I should avoid any additional load upon existing circuits, so must figure out a way to create a new circuit engine side, to control all the new electronics.

2) I have an updated (2 field) alternator currently monitored by an older single field (race only) regulator. For this to work, I have grounded the farthest field in a clockwise direction from the alternator's (+) terminal to it's grounding pin

on the edge of casing. I assume I must also connect this same grounding pin using updated (8 gauge wire) to nearby vehicle ground, perhaps a little over kill here, I'm not sure, but better safe than sorry. (As far as the old regulator goes, I will likely replace it later with a new double field unit, complete with the 2nd field field wiring mods where required, but for now, I have more than enough trouble getting what I have to work properly.

3) Given the Ammetre has already been bi-passed, I don't wish to address any wiring under the dash, unless it is absolutely necessary. So as to have some clue what is going on with the charging system, I bought a new Volt meter that I have yet to wire into the system. Hopefully... I get that right.

4) I have installed an MSD (Ready-to-Run) distributor and a MSD Blaster Coil whose instructions advised me to bi-pass the coil's original resistor. I elected to replace the old crappy looking resistor, with a new resistor supplied within the MSD coil package, leaving a resistor in the circuit, but also bi-passing it as per the instructions. (I'm not sure if the resistor now serves any useful purpose, nor do I know if it has the same resistance as did the original unit, but what I've done is done. Have my fingers crossed and hoping it works.

5) I installed a new Holley 800+ CFM carb c/w an electronic choke earlier that is currently wired through a 15 AMP fuse and into an (ignition) source beneath the dash. I am thinking it would be best to relocate this load to the suggested switchable 12V source @ fuse block within the new circuit engine side.

6) I installed a new kick-butt Vacuum Pump and reservoir back-up system to address the loss of vacuum, created by the newly installed Hughes Whiplash cam. It comes with a 40 AMP relay that calls for a switchable 12V source. I believe it also suggests the pump's (+) circuit be protected using a fuse. At the moment, I can't remember what size of a fuse, but hopefully - I can find the instructions on that issue later. I am guessing 20-30 AMP.

7) I installed a new Perma-Cool Transmission Cooler that reportedly does not require a relay. The associated in line sensor unit, requires a switchable 12V source, that when reaching the appropriate temperature, activates the fan, which calls for protection via inclusion of a 30 AMP fuse on the (-) side of the fan circuit before attaching to ground. I know not why the negative side of this fan circuit must be fused. I thought the fuse always goes on the (+) side of a circuit, but then what do I know...

8) I installed a new Flex-a-lite High Performance X-flow radiator c/w a pusher fan & shroud system and a 40 AMP relay, whose instructions call for either a switchable 12V source or (+) battery depending on whether or not you want the fan to run after the engine has been shut down. In either case, power in this circuit goes through an included circuit breaker. Relay action is dictated by an in line electronic sensor installed within the radiator (IN) hose.

9) A bunch of other mods were completed outside the topic of this thread.

10) So what remains, is still some confusion over exactly what new wiring system I should build to best furnish switched 12V power to all new relays

and the described loads.

a) I am liking the idea of installing a new fuse block on inner driver side fender well, just ahead of the original battery location, now in the trunk.

I could easily run a new 6 gauge c/w fuseable link to the fuse block (IN)

at that location, from which short 10 gauge runs could be made to near

by relays. I have no idea what fuse block would be best. I am thinking it

should be waterproof and have an on board relay to isolate not only the

block, but all subsequent circuits created therein from existing harness.

b) I am unsure if I also require a power distribution block... example: 6

gauge 1 (IN) via fuseable link from (+) starter motor with 10 gauge 4-5

(OUT) to satisfy those power demands on the load side of each relay or

if this can be achieved upon selection of the correct fuse block capable

of doing the same thing?

c) Another alternative, is going with a bank of non fused switches on

the dash, given that all circuits will be protected via fuses elsewhere.

I am guessing this option would work well with the power distribution

block design mentioned above, assuming I would find some enjoyment

in playing with switches (ON/ON/ON/ON) & OFF/OFF/OFF/OFF), likely

several times per trip. Hummm. Gotta be an easier way to do this!

I think I will call Summit Racing in the morning and actually kick some of

this same stuff around with an electronics tech.. in hopes of identifying

product(s) they may have in stock to best resolve current wiring needs.

Am I on the right track? What are your thoughts?

Sorry it's late and I am done for the night.

#14

I'm A Cole-Hersee Guy.... I just like there products......

http://www.colehersee.com/home/catalogs/

http://www.colehersee.com/home/item/cat/271/4766/

I like these.... You can split the brass bar and make some hot all the time or some Ingition switched....And take the same fuse the OEM part of the car uses so you dont have to carry other fuses like ATO's.....

Just me 2 cents.... I would how ever say to add relays to anything that will require a load over 20 amp's....

http://www.colehersee.com/home/item/.../RA-400112-DN/

And

http://www.colehersee.com/home/item/cat/204/99025/

http://www.colehersee.com/home/catalogs/

http://www.colehersee.com/home/item/cat/271/4766/

I like these.... You can split the brass bar and make some hot all the time or some Ingition switched....And take the same fuse the OEM part of the car uses so you dont have to carry other fuses like ATO's.....

Just me 2 cents.... I would how ever say to add relays to anything that will require a load over 20 amp's....

http://www.colehersee.com/home/item/.../RA-400112-DN/

And

http://www.colehersee.com/home/item/cat/204/99025/

Last edited by RacerHog; 11-03-2013 at 09:44 AM.

The following users liked this post:

68GTX440 (11-03-2013)

#16

You mentioned no8 and alternator ground. What I got out of that was you were referring to the alternator second field terminal with a 69/ earlier regulator. If so, that terminal only needs no 16 or 14, a short jumper to the case

Frankly I know this sounds like "a lot" but at this point I think I'd investigate rewiring the car. Painless and others make different types of harnesses. I'm not really in love with Painless but at least it's one solution and is pretty good quality.

Otherwise you might want to round up "a local guy" who can look this over and determine what if anything needs to be upgraded. I would look for someone who KNOWS Mopars and their wiring.

IF you can determine (and it sounds like so) that the alternator / bulkhead stuff is OK and has been dealt with, AND the ammeter bypass is properly done (read that MAD article carefully)

then I would not be afraid to add more loads off the starter relay

HOWEVER even with the bypass there is yet another caveat.

This is that the SWITCHED 12V, or so called "ignition run" is only up to so much, and often overtaxed, even with factory loads. This causes low voltage under the hood, and can cause OVER charging because the regulator sees low voltage.

In my case, I added a Junker Voyager relay box (which requires some re-wiring) and this gives me relays to operate various loads. Hi / lo beam, ignition/ regulator, fuel pump, etc. So the original ignition/ dimmer / headlight switches no longer have much power through them. They are simply turning on relays, which draw power off the starter relay/ battery cable

You can also get relay / fuse boxes from Bussmann, which can be configured several ways

Here's what I'm using, mounted on the left fender apron:

http://i.ebayimg.com/t/00-CHRYSLER-GRAND-VOYAGER-UNDERHOOD-FUSE-BOX-RELAY-CENTER-w-pigtails-04868092-/00/s/OTU2WDE2MDA=/z/8yYAAMXQEbdRnMno/$%28KGrHqR,!qwFGTqRdw8RBRnMnoCIN!~~60_35.JPG

One of the Bussmann boxes

http://img8.imageshack.us/img8/9971/img00004dw.jpg

There are folks (like on some of the 4x4 boards) who sell these pre-configured in various forms

Frankly I know this sounds like "a lot" but at this point I think I'd investigate rewiring the car. Painless and others make different types of harnesses. I'm not really in love with Painless but at least it's one solution and is pretty good quality.

Otherwise you might want to round up "a local guy" who can look this over and determine what if anything needs to be upgraded. I would look for someone who KNOWS Mopars and their wiring.

IF you can determine (and it sounds like so) that the alternator / bulkhead stuff is OK and has been dealt with, AND the ammeter bypass is properly done (read that MAD article carefully)

then I would not be afraid to add more loads off the starter relay

HOWEVER even with the bypass there is yet another caveat.

This is that the SWITCHED 12V, or so called "ignition run" is only up to so much, and often overtaxed, even with factory loads. This causes low voltage under the hood, and can cause OVER charging because the regulator sees low voltage.

In my case, I added a Junker Voyager relay box (which requires some re-wiring) and this gives me relays to operate various loads. Hi / lo beam, ignition/ regulator, fuel pump, etc. So the original ignition/ dimmer / headlight switches no longer have much power through them. They are simply turning on relays, which draw power off the starter relay/ battery cable

You can also get relay / fuse boxes from Bussmann, which can be configured several ways

Here's what I'm using, mounted on the left fender apron:

http://i.ebayimg.com/t/00-CHRYSLER-GRAND-VOYAGER-UNDERHOOD-FUSE-BOX-RELAY-CENTER-w-pigtails-04868092-/00/s/OTU2WDE2MDA=/z/8yYAAMXQEbdRnMno/$%28KGrHqR,!qwFGTqRdw8RBRnMnoCIN!~~60_35.JPG

One of the Bussmann boxes

http://img8.imageshack.us/img8/9971/img00004dw.jpg

There are folks (like on some of the 4x4 boards) who sell these pre-configured in various forms

The following users liked this post:

68GTX440 (11-03-2013)

Thread

Thread Starter

Forum

Replies

Last Post