89 dodge w150 318 weird electrical prob need fixed asap help plz!

#1

I was out plowing one day and the truck ran fine, all of a sudden next day it was seemingly running on like 4 cylinders.... But when i would raise the plow the motor cleared up and ran fine, but i had to keep a current draw on the motor. As soon as i let off the plow lever it runs like crap. Now I also had the battery go dead, checked alternator it was dead, I ran a jumper wire to one of the small 11/32" bolt studs on the back and it ran great for a day. Next day went down road and it died from a dead batt. So i got mad and installed a old chevy 350 1 wire. Its now charging and run fine yesterday. Today its doing the thing where i have to keep a big current draw on it to run. I'm pretty mad to be honest as I am not able to figure this out. Help on what is wrong would be great. I ran jumper cables all over from batt (-) to engine to ground thinking its a ground issue. doesn't help.

thanks

craig

thanks

craig

#4

#6

Grab your manual to get your acceptable range. TEST the new one too.

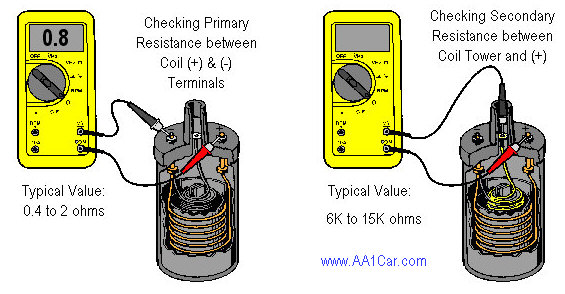

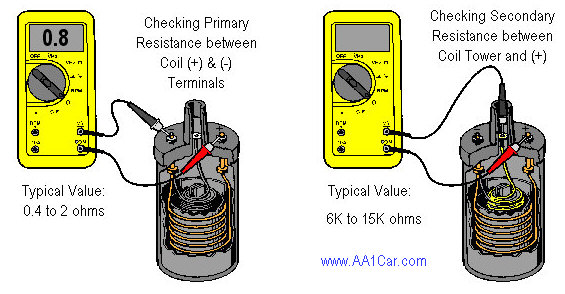

TESTING AN IGNITION COIL

WARNING: Never pull off a plug wire or the coil's high voltage output wire to test for a spark. Besides risking a severe shock, an open plug wire or coil wire will increase the voltage demands on the coil to the point where it may damage the coil. The only safe way to test for spark is to use a spark plug tester tool.

If a coil problem is suspected, measure the coil's primary and secondary resistance with an ohmmeter. If either is out of specifications, the coil needs to be replaced.

A coil can be easily bench tested with a digital 10 megaohm impedance ohmmeter. Refer to the vehicle manufacturers service information for the coil test specifications because the values can vary depending on the application.

TESTING AN IGNITION COIL

WARNING: Never pull off a plug wire or the coil's high voltage output wire to test for a spark. Besides risking a severe shock, an open plug wire or coil wire will increase the voltage demands on the coil to the point where it may damage the coil. The only safe way to test for spark is to use a spark plug tester tool.

If a coil problem is suspected, measure the coil's primary and secondary resistance with an ohmmeter. If either is out of specifications, the coil needs to be replaced.

A coil can be easily bench tested with a digital 10 megaohm impedance ohmmeter. Refer to the vehicle manufacturers service information for the coil test specifications because the values can vary depending on the application.

#8

(+) off coil to ground is 13.8v roughly (-) off coil to ground is 11.2 volts and (+) to (-) on coil is around 2.6 volts. Not sure if this is good or bad. Some input would be greatly appreciated.

thanks

craig

thanks

craig

#9

Check the RESISTANCE, not the voltage.

Pull the coil off the truck and check it.

#10

Yep,

Check Resistance in the coil itself. The coil and its windings can develope breaks that make it difficult for electricity to move thru it. So we measure resistance thru the coil. The manual will have spec or highs and lows of acceptable limits. Make sure you are within those limits. For those of us that have exploded a coil we can attest to the fact that they have oil and or an oil gel material that can leak and dry out causing issues. And man do they stink when they let go..

You can also check the resistance in the spark plug wires too. They go bad from head, cracks, vibration etc... You dont need to know the specs just make sure they are all close. Short ones will be slightly lower, longer ones will be higher..

Look at my and others' posts above and check the other items. FUEL PRESSURE needs to be checked. We need some data. Vacuum at idle, did the distributor rotate? Can you twist it as is? Confirm that cap is seated. It will run if not seated but spark will jump on the unseated side and run like crap. The 5 and 7 plug swap will run for 20 minutes some times and shake like a wet wire or ignition issue, then will flood out....

Next, this happened when plowing? Check injector connection for fit and then for moisture. Then check TPS, IAC, MAP and Intake temp sensor to make sure they are all snug. Plowing shakes stuff up.

Assuming vacuum is good and distributor didn't move, Fuel is good then back prob the hot wire to tps and give me the number. Set meter to V, 0-1. Your number at closed throttle should be under 1 volt.

Check Resistance in the coil itself. The coil and its windings can develope breaks that make it difficult for electricity to move thru it. So we measure resistance thru the coil. The manual will have spec or highs and lows of acceptable limits. Make sure you are within those limits. For those of us that have exploded a coil we can attest to the fact that they have oil and or an oil gel material that can leak and dry out causing issues. And man do they stink when they let go..

You can also check the resistance in the spark plug wires too. They go bad from head, cracks, vibration etc... You dont need to know the specs just make sure they are all close. Short ones will be slightly lower, longer ones will be higher..

Look at my and others' posts above and check the other items. FUEL PRESSURE needs to be checked. We need some data. Vacuum at idle, did the distributor rotate? Can you twist it as is? Confirm that cap is seated. It will run if not seated but spark will jump on the unseated side and run like crap. The 5 and 7 plug swap will run for 20 minutes some times and shake like a wet wire or ignition issue, then will flood out....

Next, this happened when plowing? Check injector connection for fit and then for moisture. Then check TPS, IAC, MAP and Intake temp sensor to make sure they are all snug. Plowing shakes stuff up.

Assuming vacuum is good and distributor didn't move, Fuel is good then back prob the hot wire to tps and give me the number. Set meter to V, 0-1. Your number at closed throttle should be under 1 volt.

#11

I would check all of your ground connections. Battery to motor/battery to frame. Clean your alternator connections too. Every plow truck I have looked at, including mine, eventually will have corrosion problems and if you are around salt its even worse. Plus if something is acting goofy its more likely a ground.

#12

Coil is new. still had issues with old alternator not charging and i replaced it and i believe its the voltage reg but thats in the ecu, so I believe its the computer itself, that make sense?

thanks

craig

thanks

craig

#13

I don't see how needing to keep the plow powered up would be an ignition, or computer problem.

Like mentioned, think salt and corrosion. Check all contacts especially the grounds again and clean em all.

For some reason the plow keeps it running. (?)

Am I reading this right?

You did say , (quote) "But when i would raise the plow the motor cleared up and ran fine, but i had to keep a current draw on the motor. As soon as i let off the plow lever it runs like crap."

Did you look into the plow wiring?

It might be grounding back through the plow. More likely the extra current draw is helping it to run, but killing the battery.

What happens if you disconect the plow all together? I think you have more of a charging problem, or a short some where. No power from the battery will cause it to run like crap, and or die, especially fuel injection. If there is a short then changing parts wont help.

Like mentioned, think salt and corrosion. Check all contacts especially the grounds again and clean em all.

For some reason the plow keeps it running. (?)

Am I reading this right?

You did say , (quote) "But when i would raise the plow the motor cleared up and ran fine, but i had to keep a current draw on the motor. As soon as i let off the plow lever it runs like crap."

Did you look into the plow wiring?

It might be grounding back through the plow. More likely the extra current draw is helping it to run, but killing the battery.

What happens if you disconect the plow all together? I think you have more of a charging problem, or a short some where. No power from the battery will cause it to run like crap, and or die, especially fuel injection. If there is a short then changing parts wont help.

Last edited by bboogieart; 03-04-2012 at 06:23 PM.

#14

If I had $1 for every time someone said they had a module issue, I'd be pretty well off.

Like previous stated. BASICS. My post up was just regarding a question he was asking.

Faulty grounds will cause alot of issues. My Volkswagen had a bad idle issue, but if i held the throttle open, it was better.

Replaced all the grounds and cleaned up the metal, timed it a bit, and everything was good to go.

But a number of things can be at fault. You need to start checking. Usually a visual inspection can rule out many things.

Like previous stated. BASICS. My post up was just regarding a question he was asking.

Faulty grounds will cause alot of issues. My Volkswagen had a bad idle issue, but if i held the throttle open, it was better.

Replaced all the grounds and cleaned up the metal, timed it a bit, and everything was good to go.

But a number of things can be at fault. You need to start checking. Usually a visual inspection can rule out many things.

Thread

Thread Starter

Forum

Replies

Last Post

Moparknighthawk

Off Topic

9

05-22-2010 09:10 PM

Charger 68 440

A-Body

1

09-04-2009 07:19 PM