Hydraulic camshaft wear pattern

#1

Hydraulic camshaft wear pattern

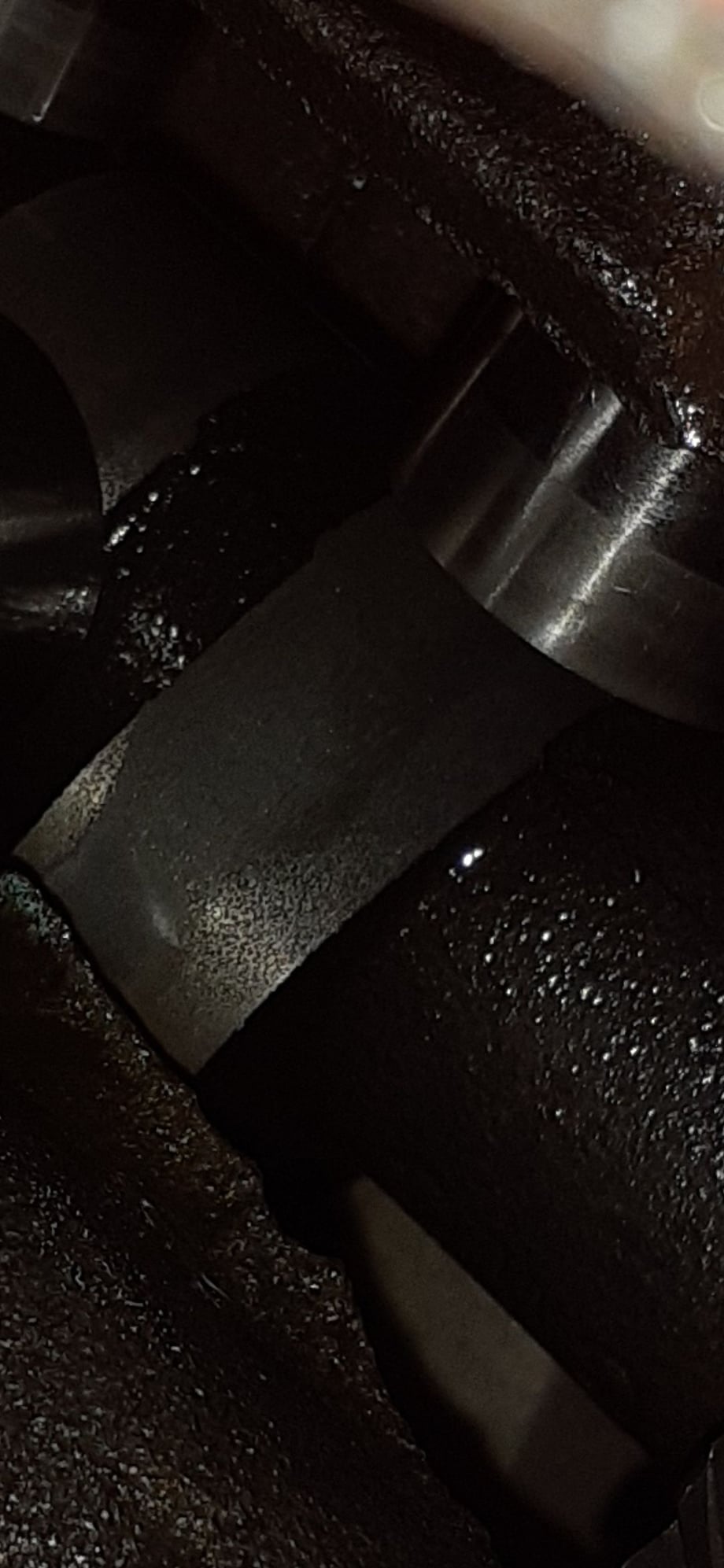

Hi! Im just courious, does this wear pattern looks normal 400 miles after break in? The engine is a new build Mopar 440 to 493cui stroker with a Comp cam xe275hl, the engine runs great without any problem and all pushrods spinning and all lobes lucks pretty much the same. Im not suspecting any problem, just courios if it looks good or not.// Jimmy

#2

Mopar Lover

Is that the same lobe?

Good. Every lobe is ground on a slight taper to make the lifter rotate. If they're all like that one it's good, I would check them all if possible.

After a break in remove the filter, cut it open and open up the paper to see how much metal is inside.

Good. Every lobe is ground on a slight taper to make the lifter rotate. If they're all like that one it's good, I would check them all if possible.

After a break in remove the filter, cut it open and open up the paper to see how much metal is inside.

#3

Is that the same lobe?

Good. Every lobe is ground on a slight taper to make the lifter rotate. If they're all like that one it's good, I would check them all if possible.

After a break in remove the filter, cut it open and open up the paper to see how much metal is inside.

Good. Every lobe is ground on a slight taper to make the lifter rotate. If they're all like that one it's good, I would check them all if possible.

After a break in remove the filter, cut it open and open up the paper to see how much metal is inside.

#5

#7

Thanks! I just wanted to try the 15w-50 oil but i think i not need it. I have good preassure with 10w-30, 20 psi at idle with that oil, i have a high volyme pump and lifter comp cam 822-16 and 3/8 pushrods with oiling through, i think thats why i have little lower preassure on idle, Mopar not need it and have oiling from 4:th cambearing through shaft, but the lifter and pushrods just have it when i buy the parts so i let i be like that, not bad with good oiling to rockers😊, 7 quarter oil pan not running empty to. I have .002" clearance on both main and rod bearing, not to loose and not to tight, this engine not going to see more than 6000 rpm. The engine runs really great, i have build this engine myself and im really happy it be a succes😊

#8

Super Moderator

I remember a time when straight 50w is what we used, infact I have a new five gallon jug of it in the basement.

#9

Yes thats true, i dont know whats best, i can think the little heavier oil can recist better with little looser bearing clearance and the preassure stay a bit higher in warm weather

#10

Super Moderator

I would not use that 50W in a hydraulic cam motor 25 years ago it was for solid cam race motors but now its synthetic oil 10 30W or 10 40W depending on oil pressure. The parasitic power loss of the 50W makes it unusable.

#11

Ok, i just tried it and can not notice any different other than just higher oil preassure, but i belive im going to try 15w-40 instead

#13

Mopar Lover

Let me make a point here.... We said we are dealing with a High Volume Pump.... NOT a High Pressure Pump.... That will make a difference...

So for me, when I look at the 20 PSI, I think ok, we are dealing with Volume and not pressure. You have to be careful with the Volume. It can Twist the Oil Pump Shaft Drive off if you get to crazy.

Modding the Oiling System to take volume is a good thing, dont get me wrong.

I dont see any problem with 20PSI at Idle and as long as it has 60-65PSI @ 6,000 RPM i would say your in the safe zone...

Just my 2 cents

Thanks for sharing... Great Topic...

So for me, when I look at the 20 PSI, I think ok, we are dealing with Volume and not pressure. You have to be careful with the Volume. It can Twist the Oil Pump Shaft Drive off if you get to crazy.

Modding the Oiling System to take volume is a good thing, dont get me wrong.

I dont see any problem with 20PSI at Idle and as long as it has 60-65PSI @ 6,000 RPM i would say your in the safe zone...

Just my 2 cents

Thanks for sharing... Great Topic...

#14

Let me make a point here.... We said we are dealing with a High Volume Pump.... NOT a High Pressure Pump.... That will make a difference...

So for me, when I look at the 20 PSI, I think ok, we are dealing with Volume and not pressure. You have to be careful with the Volume. It can Twist the Oil Pump Shaft Drive off if you get to crazy.

Modding the Oiling System to take volume is a good thing, dont get me wrong.

I dont see any problem with 20PSI at Idle and as long as it has 60-65PSI @ 6,000 RPM i would say your in the safe zone...

Just my 2 cents

Thanks for sharing... Great Topic...

So for me, when I look at the 20 PSI, I think ok, we are dealing with Volume and not pressure. You have to be careful with the Volume. It can Twist the Oil Pump Shaft Drive off if you get to crazy.

Modding the Oiling System to take volume is a good thing, dont get me wrong.

I dont see any problem with 20PSI at Idle and as long as it has 60-65PSI @ 6,000 RPM i would say your in the safe zone...

Just my 2 cents

Thanks for sharing... Great Topic...

#16

Super Moderator

I'm going to mention something that I touched on earlier and that's parasitic power loss and oil pressure and volume.

On every big block of mine I have used a half inch pickup tube, some guys think it is over kill but if everything is the same between 3/8" and 1/2" the 1/2" will require less power to pull the same volume of oil. I also blend the oil pump cover including the 90° bend and the ports in the filter boss.

The viscosity of the oil can be used to achieve the desired oil presser with the thinner oil having less parasitic power loss.

I'm a firm believer in freeing up power and finding an additional 10 to 20 hp in you oiling system is a no brainer.

On every big block of mine I have used a half inch pickup tube, some guys think it is over kill but if everything is the same between 3/8" and 1/2" the 1/2" will require less power to pull the same volume of oil. I also blend the oil pump cover including the 90° bend and the ports in the filter boss.

The viscosity of the oil can be used to achieve the desired oil presser with the thinner oil having less parasitic power loss.

I'm a firm believer in freeing up power and finding an additional 10 to 20 hp in you oiling system is a no brainer.

#17

Mopar Fanatic

Be very careful about what oil you choose. I believe Joe Gibbs oil ranks low. 540RAT (engineer) broke the wear code issue on his blog. He tested about 300 oils and the loss of cam lobes aren't from the lack of zinc, break-in procedure or anything else but rather from overall crappy oil with low PSI results. Right now 5w30 Quaker State Full Synthetic is your best protection and ranked a whopping 153000 PSI result.

#18

Hello, re. camshaft wear:

I bought a new 440 engine from CME (Carolina Machine Engines) and drove it about 1000 miles. Now the camshaft lobes of intake valve in cylinder 1 and 4 are totally worn down. I used the correct oil (1400 ppm zinc) and I have not revved the engine. Just a couple of sub-zero starts.What do you think happened?

By the way, are you a Swede too? I see Sweden as residence on you bio

I bought a new 440 engine from CME (Carolina Machine Engines) and drove it about 1000 miles. Now the camshaft lobes of intake valve in cylinder 1 and 4 are totally worn down. I used the correct oil (1400 ppm zinc) and I have not revved the engine. Just a couple of sub-zero starts.What do you think happened?

By the way, are you a Swede too? I see Sweden as residence on you bio

#19

Mopar Fanatic

Some people don't agree with factual data provided by engineering professionals. I feel the need to help people in trouble. It's your choice or not to follow these instructions.

I'm assuming you followed the high zinc and low wear break-in oil along with high revs for 20 minutes. All is the perfect recipe for disaster as you found out. Here is a procedure from an "expert engineer 540RAT" on new camshaft procedures. It's your choice to follow his instructions are try doing all over again what you did the first time and pray for a different result. 63. The Proper Start-Up/Break-In Process to use after a Flat Tappet engine “Build or Rebuild” to avoid Wiped Lobes, How Flat Tappet Cams are REALLY Lubricated, and Recommended Assembly Lube Information

63. The Proper Start-Up/Break-In Process to use after a Flat Tappet engine “Build or Rebuild” to avoid Wiped Lobes, How Flat Tappet Cams are REALLY Lubricated, and Recommended Assembly Lube Information

NOTE: Information on recommended “Assembly Lube”, was added to the end of this Tech Article in Fall 2023.

This information can be found in various places in my Blog. But, with my Blog and its Q&A Section being so enormous, it can sometimes be hard to find specific information. So, I have put this information into its own Tech Article to make it easy to be aware of and convenient to find.

It is no secret that the long drawn-out and complicated so-called break-in procedures you read about on Automotive Forums, do NOT work. Because engines continually fail when that crazy practice is used. Yet, people who should know better, continue to recommend them. So, those who recommend that nonsense, are responsible for the engine failures that follow.

People should never blindly follow advice from utterly unqualified people on Automotive Forums and other Automotive sources, no matter who they are, or what Company they may represent.

But, here in my Blog you will find the Truth and the Facts, that you cannot find anywhere else. And I back-up everything I post, with hard Engineering Test Data. The whole reason I started my Blog in the first place, was so that people would finally have a place to go where they can find the Facts. Because most other Automotive sources provide nothing but BAD information.

Here is what you should follow for a successful Start-Up/Break-In of a New or Rebuilt traditional pushrod flat tappet engine:

– With an engine that is built properly with quality parts, there is no concern at all about using synthetic oil during initial fire-up or so-called Break-In. There never was a problem with putting synthetic oil in a brand new engine. That was just another MYTH spewed by people who have no idea what they are talking about. Many brand new factory vehicles, especially High Performance vehicles, come factory-filled with synthetic oil. And those engines have no so-called Break-In problems.

– Build your engine as you normally would, using the normal valve springs, etc, with it ready to drive down the road right after it is fired up, and everything checks out good, such as no leaks, etc.

– Do NOT use so-called Break-In oil which is THE WORST motor oil on the market.

– Do NOT use any aftermarket motor oil additives.

– Do NOT use a crazy thick motor oil. Use a thinner oil, ideally 5W30, as long as your engine is capable of making acceptable “HOT” oil pressure with that oil. Depending the oiling system capability, and the bearing clearances, some traditional American V-8 engines may require a high volume oil pump to do that, which is preferred anyway. Thinner oil with a high volume oil pump is FAR SUPERIOR to thicker oil with a standard volume oil pump. Because thinner oil with a high volume oil pump provides increased oil “flow”. And flow is lubrication, which is what we want.

– Do NOT follow any ridiculous, complicated 20 minute break-in procedure, which typically includes among other things, holding the engine at an absolutely unnecessary moderately high rpm, which can do more harm than good, and can often CAUSE wiped lobes. Many people have contacted me for help, after they experienced wiped lobes when they followed that kind of misguided procedure. Also, keep in mind that flat tappet cams are NOT lubricated only by splash lubrication. That is another total MYTH (more on that below).

– Use only a Highly Ranked, High Performance motor oil from my Wear Protection Ranking List, from first fire, on, and you won’t even have to think about Break-In. You do NOT need to use different oils at different times. Case in point: Even automotive factories do NOT use break-in oils. Not even in their Highest Performance vehicles. They just use the normal oil that is called for in a given vehicle. My recommendation is 5W30 Quaker State Full Synthetic, API SP motor oil, or 5W30 Amsoil Signature Series, API SP motor oil. Then change it at reasonable intervals.

– Just as soon as the engine is running and all is good, back the vehicle out of the garage, and go drive it the way you normally plan to use it. That’s it! This is THE BEST Start-Up/Break-In Process” that works every time and will not wipe flat tappet lobes, if you follow all my recommendations here in this article, especially using only a highly ranked, high performance motor oil that produces a high psi value in my Engineering Torture Test on motor oil. Start-Up/Break-In could not be more simple.

– Be aware that so-called break-in is also largely an overblown MYTH, because engines will break-in almost immediately on their own. That is because the engine components are automatically forced seat in very, very quickly to carry the load being applied to them.

– I’ve built many, many engines over the years. So, I’ve tested many different ways of breaking them in, to find out if there is a certain way that might better than the others. I’ve broken them in slow and easy, hard and fast, and everything in between. What I’ve found is that it makes absolutely NO difference at all how they are broken-in. You don’t have to do anything special at all.

– That is real world experience which proves and backs-up what I said above, about engines breaking-in almost immediately all by themselves. Therefore, whatever you do shortly after firing up a rebuilt flat tappet engine, makes no difference at all.

– Bottom Line: If an engine is built properly, with quality parts, and a proper “high performance” motor oil is used that is capable of supporting that particular engine’s needs, then you don’t need to be concerned about how it’s “broken-in”, because it just DOES NOT matter.

– The above methodology that I use and highly recommend works extremely well, not because it’s magic, but because it follows the Engineering FACTS. When we make use of the Facts, we don’t have any problems.

– The number one thing that matters when it comes to motor oil wear protection capability, is the “psi value” that an oil is capable of producing in my Engineering Torture Test on motor oil (an oil’s zinc level is NOT important, no matter what anyone tells you. Today’s modern High Performance motor oils are FAR BETTER than the old obsolete high zinc oils). In addition to that, it is also important to use the correct motor oil viscosity.

I'm assuming you followed the high zinc and low wear break-in oil along with high revs for 20 minutes. All is the perfect recipe for disaster as you found out. Here is a procedure from an "expert engineer 540RAT" on new camshaft procedures. It's your choice to follow his instructions are try doing all over again what you did the first time and pray for a different result. 63. The Proper Start-Up/Break-In Process to use after a Flat Tappet engine “Build or Rebuild” to avoid Wiped Lobes, How Flat Tappet Cams are REALLY Lubricated, and Recommended Assembly Lube Information

63. The Proper Start-Up/Break-In Process to use after a Flat Tappet engine “Build or Rebuild” to avoid Wiped Lobes, How Flat Tappet Cams are REALLY Lubricated, and Recommended Assembly Lube Information

NOTE: Information on recommended “Assembly Lube”, was added to the end of this Tech Article in Fall 2023.

This information can be found in various places in my Blog. But, with my Blog and its Q&A Section being so enormous, it can sometimes be hard to find specific information. So, I have put this information into its own Tech Article to make it easy to be aware of and convenient to find.

It is no secret that the long drawn-out and complicated so-called break-in procedures you read about on Automotive Forums, do NOT work. Because engines continually fail when that crazy practice is used. Yet, people who should know better, continue to recommend them. So, those who recommend that nonsense, are responsible for the engine failures that follow.

People should never blindly follow advice from utterly unqualified people on Automotive Forums and other Automotive sources, no matter who they are, or what Company they may represent.

But, here in my Blog you will find the Truth and the Facts, that you cannot find anywhere else. And I back-up everything I post, with hard Engineering Test Data. The whole reason I started my Blog in the first place, was so that people would finally have a place to go where they can find the Facts. Because most other Automotive sources provide nothing but BAD information.

Here is what you should follow for a successful Start-Up/Break-In of a New or Rebuilt traditional pushrod flat tappet engine:

– With an engine that is built properly with quality parts, there is no concern at all about using synthetic oil during initial fire-up or so-called Break-In. There never was a problem with putting synthetic oil in a brand new engine. That was just another MYTH spewed by people who have no idea what they are talking about. Many brand new factory vehicles, especially High Performance vehicles, come factory-filled with synthetic oil. And those engines have no so-called Break-In problems.

– Build your engine as you normally would, using the normal valve springs, etc, with it ready to drive down the road right after it is fired up, and everything checks out good, such as no leaks, etc.

– Do NOT use so-called Break-In oil which is THE WORST motor oil on the market.

– Do NOT use any aftermarket motor oil additives.

– Do NOT use a crazy thick motor oil. Use a thinner oil, ideally 5W30, as long as your engine is capable of making acceptable “HOT” oil pressure with that oil. Depending the oiling system capability, and the bearing clearances, some traditional American V-8 engines may require a high volume oil pump to do that, which is preferred anyway. Thinner oil with a high volume oil pump is FAR SUPERIOR to thicker oil with a standard volume oil pump. Because thinner oil with a high volume oil pump provides increased oil “flow”. And flow is lubrication, which is what we want.

– Do NOT follow any ridiculous, complicated 20 minute break-in procedure, which typically includes among other things, holding the engine at an absolutely unnecessary moderately high rpm, which can do more harm than good, and can often CAUSE wiped lobes. Many people have contacted me for help, after they experienced wiped lobes when they followed that kind of misguided procedure. Also, keep in mind that flat tappet cams are NOT lubricated only by splash lubrication. That is another total MYTH (more on that below).

– Use only a Highly Ranked, High Performance motor oil from my Wear Protection Ranking List, from first fire, on, and you won’t even have to think about Break-In. You do NOT need to use different oils at different times. Case in point: Even automotive factories do NOT use break-in oils. Not even in their Highest Performance vehicles. They just use the normal oil that is called for in a given vehicle. My recommendation is 5W30 Quaker State Full Synthetic, API SP motor oil, or 5W30 Amsoil Signature Series, API SP motor oil. Then change it at reasonable intervals.

– Just as soon as the engine is running and all is good, back the vehicle out of the garage, and go drive it the way you normally plan to use it. That’s it! This is THE BEST Start-Up/Break-In Process” that works every time and will not wipe flat tappet lobes, if you follow all my recommendations here in this article, especially using only a highly ranked, high performance motor oil that produces a high psi value in my Engineering Torture Test on motor oil. Start-Up/Break-In could not be more simple.

– Be aware that so-called break-in is also largely an overblown MYTH, because engines will break-in almost immediately on their own. That is because the engine components are automatically forced seat in very, very quickly to carry the load being applied to them.

– I’ve built many, many engines over the years. So, I’ve tested many different ways of breaking them in, to find out if there is a certain way that might better than the others. I’ve broken them in slow and easy, hard and fast, and everything in between. What I’ve found is that it makes absolutely NO difference at all how they are broken-in. You don’t have to do anything special at all.

– That is real world experience which proves and backs-up what I said above, about engines breaking-in almost immediately all by themselves. Therefore, whatever you do shortly after firing up a rebuilt flat tappet engine, makes no difference at all.

– Bottom Line: If an engine is built properly, with quality parts, and a proper “high performance” motor oil is used that is capable of supporting that particular engine’s needs, then you don’t need to be concerned about how it’s “broken-in”, because it just DOES NOT matter.

– The above methodology that I use and highly recommend works extremely well, not because it’s magic, but because it follows the Engineering FACTS. When we make use of the Facts, we don’t have any problems.

– The number one thing that matters when it comes to motor oil wear protection capability, is the “psi value” that an oil is capable of producing in my Engineering Torture Test on motor oil (an oil’s zinc level is NOT important, no matter what anyone tells you. Today’s modern High Performance motor oils are FAR BETTER than the old obsolete high zinc oils). In addition to that, it is also important to use the correct motor oil viscosity.

Last edited by Kuvasz101; 02-28-2024 at 05:29 AM.

Thread

Thread Starter

Forum

Replies

Last Post

Mopar493

General Technical Questions

10

11-10-2019 09:17 PM